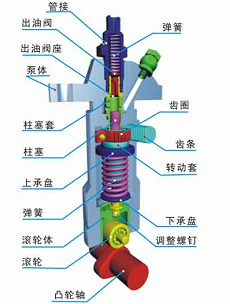

Plunger,as a device that is applied to the injection pump of the diesel in automotiveindustry, it is introduced in the case below. The injection pump is the mostimportant part in fuel supply system of diesels. It is also called the heart ofthe diesel, and its fundamental function is to transmit the high pressurediesel fuel in a fixed time and quantity.

Plunger andBarrel Assembly undertake high mechanical load. It is driven by cam, and thepressure of fuel is increased. A relatively high temperature of plunger iscaused by the heat, which is created by friction of high speed reciprocalmotion. The materials for manufacturing the plunger should be in highmechanical strength, enough rigidity and good toughness. It requires high wearresistance, high corrosion resistance, and low thermal expansion coefficient.Also, the stability of metallographic structure and good machinability areneeded. Generally, tool steel CrWMn and rolling bearing steel GCr15 which is inhardness range of HRC62-65. In addition, the shape and structure of plunger arerelatively simple but it requires high consistency for all sides.

Fuel injection pump

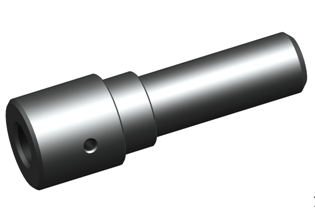

Thereare 3 machining operations involved in plunger machining, and they are Roughing,Finishing and Fine-finishing. Also, thermal treatment is engaged. The machiningprocesses would be: External Rough Turning - Parting - Face and External ChamferTurning on the position basis of External Rough - Medium Hole Drilling, Counterboring,Reaming and Internal Chamfering - Cleaning -Roughness and Diameter Check forMedium Hole - External Finishing on the position basis of Medium Hole -Cleaning – Medium and External Rough Grinding on the position basis of MediumHole - Cleaning - Oil Entrance Drilling and Oil Outlet Drilling on the positionbasis of Large External - Cleaning - Oil Entrance Counterboring and Oil OutletCounterboring on the position basis of Large External - Cleaning.

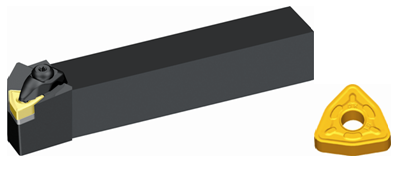

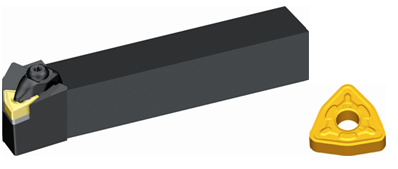

External Rough Turning-External Turning Tools with 95° Entering Angle

Tool:DWLNR2525M08

Insert:YBC252/WNMG080412-DR

Cutting data:V=200m/min f=0.3mm/r ap=2mm

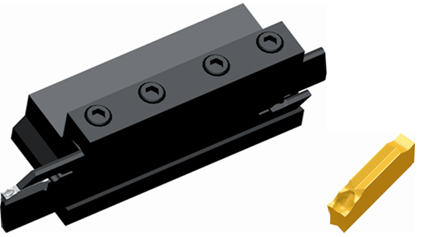

Parting- "Little Squirrel" Series of External Parting Tools

Tool:刀座QZS2526、刀板QEES26N

Insert:YBC251/ZPES02502-MG

Cutting data:V=110m/min f=0.05mm/r

Face Turning-External Turning Tools with 95° Entering Angle

Tool:DWLNR2525M08

Insert:YBC252/WNMG080412-DR

Cutting data:V=240m/min f=0.3mm/r ap=2mm

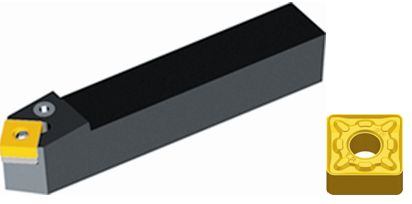

External Chamfering of Face-External Turning Tools with 45°Entering Angle

Tool:PSDNN

Insert:YBC252/SNMG120408-DM

Cutting data:V=

Medium Hole Drilling- Solid Carbide Drills

Tool:1534SU03C-1060

Cutting data:n=2200r/min f=0.18mm/r

Medium Hole Counterboring-Solid Carbide Counterboring Tools

Tool:扩孔钻φ10.8*85*130

Cutting data:n=2800r/min f=

Medium Hole Reaming- Solid Carbide Reamers

Tool:铰刀φ10.9*85*130

Cutting data:n=300r/min f=

Medium Hole Chamfering- Solid Carbide Spot Drills

Tool:1143SC90-1200

Cutting data:n=1600r/min f=0.28mm/r

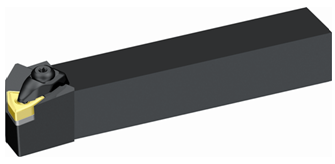

External Finish Turning for Steps-External Turning Tools with 95° EnteringAngle

Tool:DWLNR

Insert:YBC152/WNMG080404-DF

Cutting data:V=

Oil Entrance & Oil Outlet Drilling- Solid Carbide Drills

Tool:1534SU03C-0340

Cutting data:n=6000r/min f=0.09mm/r

Oil Entrance & Oil Outlet Counterboring-

Solid Carbide Counterbore drills

Tool:Counterboredrillφ3.5*10*56

Cutting data:n=2800r/min f=